Things To Know More About The Carbide Cutting Tools

Carbide may be a derivative of hard metals. If we trace back in History, hard metal was extensively utilized in industrial operations and ventures until the onset of the economic revolution.

With changing needs and aspirations of the people, researchers went on to make a way harder substance, harder than the hard metals. Scientists named this invention as carbide. Later, years of relentless research revealed that if Iron (Fe) is reacted with harder carbide substances, the results may be a harder tool.

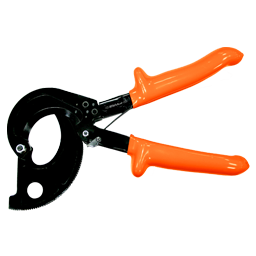

Carbide cutting tools are used for cutting and shaping a number of sturdiest substances. Most of the Carbide Cutting Tools USA has carbide coating at the top of the tip of that tool that has the top of the tool.

Just after the invention of this device, the economic revolution embraced the new technologies and also carbide cutting fixtures. The carbide cutting tools proved to be an absolute necessity within the industrial applications thanks to its worthy and wide use.

This kind of tool, generally, prefers the use of particles of carbides just like the tungsten carbide, titanium carbide, and tantalum carbide grains and a number of other carbide derivatives. The method during which carbide cutters are prepared involves heating of carbide during a furnace up to a temperature of a minimum of 1400 degrees Celsius. This makes such quite devices extremely useful even in extreme temperatures.

Application areas:

To manufacture machine To shape a good range of tools To produce prototypes from metal to get rid of material from a uniform block of metal To lend leading-edge finished output Industrial Carbide Cutting Tools USA extensive applications in industry as they're immune to strength, heat and chemical reactions (most of the times) To cut hard metals like steel and iron To prepare metal molds and castings To prepare cutting devices for shaping plastic or wood To prepare screws, nuts and bolts

Benefits of Carbide Cutting Tools

It is highly rigid and hard thus helping its primary cause; to chop harder metals Its unmatched resistance against abrasions Resistant to thermal deformations hence materials with a low boiling point also is worth shaping with it High modulus of elasticity hence justifies its use within the molding of relatively soft materials Chemical inertness helps to remain 'noble' while handling a number of the foremost fiercely active metals. Chemical inertness helps the cutter people to urge their due output without the probability of adulterants whatsoever High torque index that creates it faster than other tools available within the industry High compressive strength makes it easier to figure with metals and crystals

Carbide cutter tips are an amalgam from a compound of carbon and tungsten chemically referred to as tungsten carbide. Tungsten carbide is harder than most metals and is considered 'stable' towards chemical reactions. Hence carbide is extremely much popular as a cutter due to its hardness alongside its chemical inactiveness.

For more info :-

Comments

Post a Comment